Addressograph Graphotype

6100 Series

G1 Series

Authentic WWII Notched

dog tags are available custom imprinted with your

information thru our on-line

catalog.

Please visit

our on-line

catalog

to purchase notched dog tags.

The Addressograph 6100 series machines are manual

machines used to produce debossed/embossed metal

plates that were used with the Addressograph

imprinters and addressing machines. The 6100

or G1 series represents an entry level unit that was

intended for the smaller business or those that did

not have the need or volume capacity of the larger

electric models such as the 6300 series and 6400

series machines.

In the 6100 series class of machines there were many

different variations just as with all the other

classes of Graphotypes. Here we will focus

upon two main variants, the 6140 and 6185.

Where does the name G1 come from? Why do

people refer to these machines as a Type G1

Graphotype? As stated throughout this web site

Addressograph-Multigraph had literally thousands of

different individual machines with hundreds of

classes and even more variations within the

individual classes. The G1 was indeed one

classification of the manual Graphotype but it is

used often synonymously with the 6100 series class

of machines across the board. There are very

little differences between the individual variations

of the machines and most parts interchange.

The main difference between the variations of the

6100 or G1 class of machines is the way that the

operator selects the characters to be imprinted.

It is said that a competent operator can make about

25-45 tags per hour with this style of machine.

Physical characteristics of this style machine are

30" Wide, 15" Deep, 18" Tall - Weight is between 125

and 150 pounds dependant upon options and model.

6140 Series

G1 Series

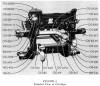

This manual machine utilizes a knob

and round dial to select the text to be imprinted.

The operator would grasp the knob located on the

left hand side of the machine and would rotate the

knob either clockwise or counterclockwise to change

the selection of the dies to choose the desired

character to be printed. The operator would

know which die and character was selected by viewing

a character map imposed on the face of a indicating

dial located on the top of the machine.

The above photograph illustrates one

part of the machine that is most often lost on this

style of machine - the cast iron clip board.

There is a hole located in the casting of the

machine in the upper right hand corner that the clip

board fit into. With these clipboards being

cast iron, many of them have been damaged, cracked

or broken. Others were just lost or misplaced.

None-the-less, the clip board is an original

equipment item that is very hard to locate.

These machines are cast iron, they

weight approximately 110 lbs. From the factory

they came painted black and many were sporting

yellow or gold pen striping.

You will notice the handle on the

right hand side of the machine. This handle is

mounted to a heavy cast iron curved arm that is

pulled forward toward the operator. When the

operator pulls this handle forward it activates the

springs and stamping mechanism causing the dies and

punches to move together and emboss or deboss the

blank plate. There is a loaded spring that

actually pops the die and punch together at the end

of the stroke of the actuator arm.

From the rear of the machine you can

clearly see the "knuckle-joint", that is used to

transfer the rotation of the die selection knob to

the indicator dial. This joint is the most

common lost part on these older machines. The

"knuckle-joint", acts much like a jointed socket

adapter - it allows for the transfer of movement and

energy at an angle. From the rear one can see

in more detail the die and punch carousel.

Parts and Components

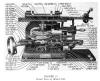

The above is a photograph of the

carriage assembly. The carriage assembly is

the part of the machine that moves from left to

right and holds the blank that is being imprinted.

Missing from this photograph are is the Jaw/Clamp

assembly. The Jaw/Clamp assembly is actually

the physical part that holds the blank and the

carriage assembly is what held the transported the

Jaw/Clamp assembly.

This is a up close photograph of the

die and punch carousel. This man is removing

and replacing dies/punches from the top of the

carousel. Notice that he is pulling back the

retaining spring that is used to hold the dies and

punches in the correct location at the proper

height.

In this photograph this man is

removing and replacing dies and punches from the

lower portion of the carousel. On the bottom

row the man must release the tension on the

retaining springs to allow freedom of movement for

the individual dies and punches.

6185 Series

This machine works on the same

principle as the 6140 machine but there are some

dramatic differences in the why the operator

interfaces with this machine.

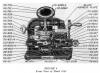

In this front view of the machine

clearly you can see the round wheel located on the

left hand side of the machine. This wheel is

on a slight angle and protrudes outward toward the

operator from the front of the machine. The

operator uses this wheel to select the proper

character to be imprinted. The selection of

the character is confirmed by a visual indicator on

the scale located at the top of the machine.

As the operator rotates the wheel a pointer moves

left to right or right to left and the pointer

indicates which character has been dialed up for

imprinting.

The photograph of this machine also

shows another option that was available on these

machines but is NOT often found on the average

specimen sold today. The machine above clearly

illustrates two forms of tag flatteners. Tag

flatteners were used to flatten tags that had been

imprinted to remove any curve created during the

imprinting process and to flatten the peaks of the

imprinted text to a proper and uniformed height.

When making addressing plates it is important to

have all the text at the same height or depth so

that it will transfer evenly when placed in an

imprinter or embosser. Look at a modern day

credit card, the raised text is all the same style

and height so that if a manual receipt imprinter is

used the text will transfer to the receipt.

There are two different tag

flatteners visible in the photograph above and

below.

6100 or G1 Series Photo Gallery